Quality Control

PCBA Quality Control

During the production, every stage is diligently monitored and validated through rigorous closed-loop systems to ensure that the boards follow the corresponding IPC Class 2, 3 or MIL-SPEC standards.

At the end of the manufacturing process, it is crucial that all the PCBAs are duly assessed by an Automated Optical Inspection (AOI), ICT / FCT and Visual Checks. Depending on your application, the boards will also undergo another set of checks, and customized QCs to make sure they perform as expected in their real-life environment.

To guarantee a flawless PCB Assembly, below is the list of the main tests performed

First Article Inspection is thoroughly inspecting and testing the first assembled board of the batch. It ensures that there are no assembly errors or defects prior to manufacturing the full run. During FAI, the PCBA is carefully inspected after every step of the production, and the Quality Engineer will conduct measurements to confirm the value of all assembled passive components, along with the placement and Part Numbers of all BOM Items.

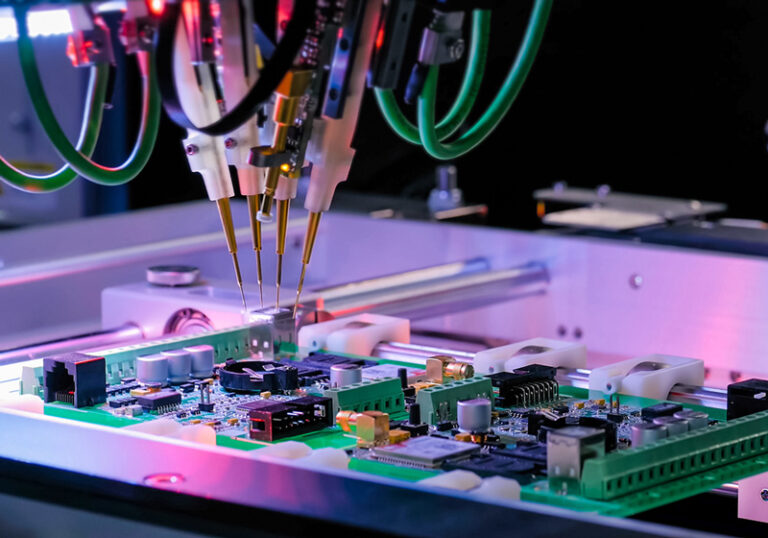

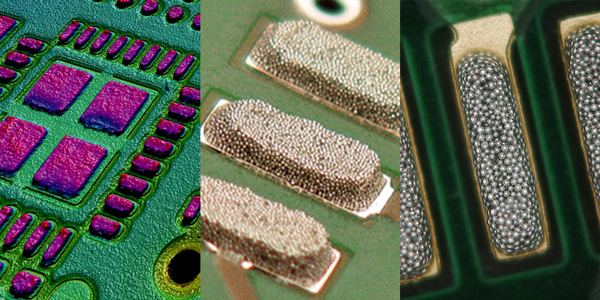

Automated Optical Inspection is an efficient and accurate inspection machine that detects assembly errors.

AOI has arrays of colored LEDs that are directed on the subject board. High Resolution cameras will detect the reflected colored light from the solder and the image processing software will identify: Missing or misplaced components, soldering short circuits, disconnected components, components misalignment, etc.

At Fox EMS, this is a standard and mandatory process that is performed on all the boards that we deliver.

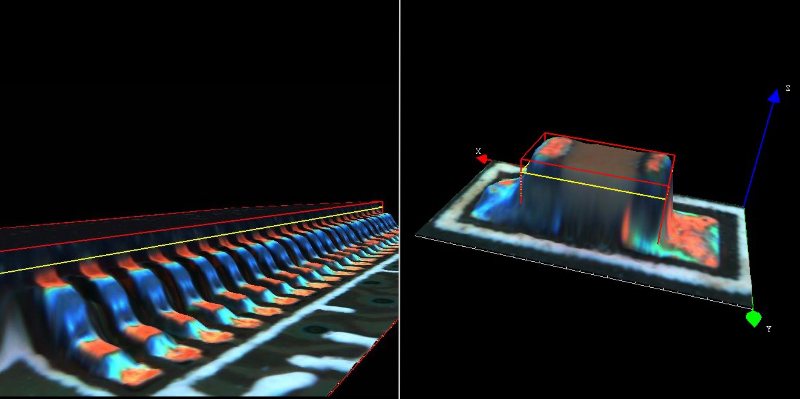

Solder Paste Inspection is conducted right after the Solder Paste Printer and before the SMT Pick and Place machine. As its name indicates, it inspects the solder paste deposits on the SMD pads of bare printed circuit board (PCBs).

It is observed that most of the solder joint defects in a PCBA are because of improper solder paste printing. At Fox EMS, to ensure the highest quality possible, an SPI is deployed to reduce or even eliminate all boards with solder joint defects.

On BGA, QFN or other Lead-Less package components, the pads are underneath the component body. Once soldered onto the PCB, the connections won’t be visible. Therefore, the Automatic Optical Inspection (AOI) machine won’t be able to detect potential defects.

X-Rays can penetrate the IC package, and will reflect on Higher Density features such as the metal connections. Using image processing, the board can be analyzed to detect missing solder joints and component misalignment.

For a robust assembly process, at Fox EMS we ensure that an X-ray inspection is performed on boards with such SMD Components.

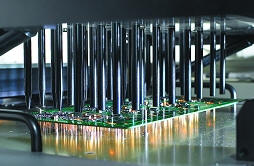

One common method to perform Functional Testing is to use a fully customized Test Fixture. The fixture will power up the board, measure data from designated Test Points, and simulate the operating environment. At the end, all test parameters will be carefully verified ensuring that the Device Under Test (DUT) meets the requirements and performs as expected in real life.

At Fox EMS, we work closely with our clients to understand their design, implement their existing test method, suggest a new one or optimize the whole process for Mass Production.

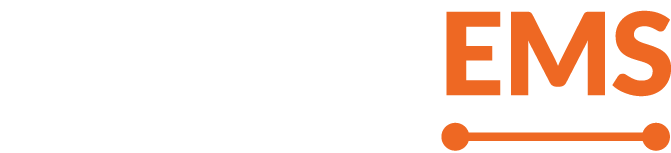

During in-circuit tests, all components of the printed circuit board (PCBA) are individually tested one at a time. A software compares the measured values to the simulated Circuit Schematics. The board is also tested for Short and Open Circuits.

At Fox EMS, an ICT can be done with a Flying Probe for a small production, or with a customized Test Fixture for Mass Production.

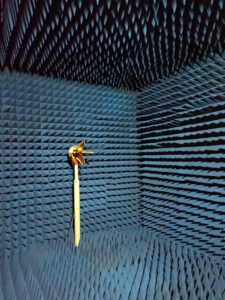

Anechoic means Non-Reflective and Non-Echoing. An Anechoic Chamber is a shielded room with radio-wave absorbing material designed to provide an environment free of unwanted ambient interference and signals. This creates an accurate, stable, repeatable, and ideal environment for testing Electronics Boards such as radar systems, antennas, sensors, etc.

At Fox EMS, a big number of our Military & Defense, Aerospace and Communication boards needs to be tested in these chambers.

Burn In Test (BIT)

Hi-Voltage Testing

Thermo-Cycling

Vibration